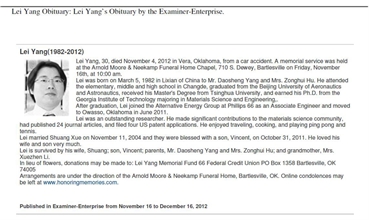

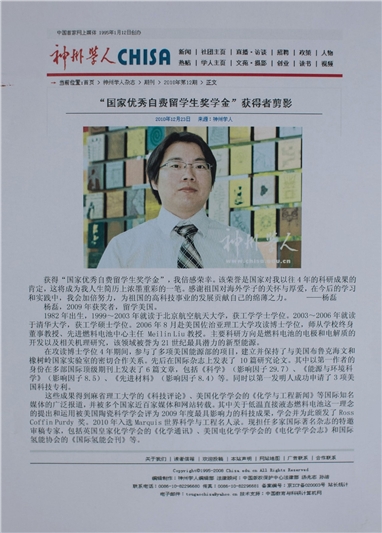

国际青年化学家奖陈述材料——杨磊

Among all types of fuel cells, solid-oxide fuel cells (SOFCs) offer great prospects for the most efficient and cost-effective utilization of a wide variety of fuels such as hydrocarbons, coal gas and gasified biomass [1]. The critical technical barrier to fuel flexibility is the vulnerability of the state-of-the-art anode to coking and sulfur poisoning [2]. In addition, the high operating temperatures of SOFCs increase costs and reduce system operation life [3]. Thus, in order to make SOFCs fully fuel-flexible, cost-effective power systems, the issues of anode tolerance to coking and sulfur poisoning as well as the slow ionic conduction in the electrolyte and the sluggish kinetics at the cathode need to be addressed. In a broader scientific context, the chemical and electrochemical mechanisms that lead to both of these issues and the phenomena that could prevent them should be investigated in order to best optimize the materials and microstructure of SOFCs for excellent performance and stability.

CONTRIBUTIONS AND RESULTS

1. Discovered a new ionic conductor and probed the atomic environment and surface species

A new ionic conductor, the barium zirconate-cerate codoped with Y and Yb ions (BZCYYb), was developed via extensive experimental and computational study. This material displayed the highest ionic conductivity below 750oC of all known electrolytes for SOFCs applications (Fig. 1 A) [4]. A systematic electrochemical analysis revealed that the conductivities were sensitive to doping and partial pressure of oxygen, hydrogen, and water; it can transport both proton and oxygen ion under the fuel cell operating conditions. The interrelationship between lattice dynamics, atomic environment and ion transport was established by synchrotron-based X-ray diffraction, extended X-ray absorption fine structure and impedance spectroscopy. It was found that two dopants on the B-site function in a cooperative fashion to significantly improve the ionic conductivity. The enhanced ion transport could be reasonably attributed to the slight distortion of the lattice structure and less disturb of the local atomic environment. Further, an in-situ Raman spectroscopy was employed to probe the surface species under fuel cell operating conditions. Upon exposure to humidified fuel, the presence of the modes in the 3100-3700 cm-1 range is strongly indicative of multi-layered surface water molecules, as modes at higher wave-numbers correspond to subsequent layers of water with weaker hydrogen bonds. Its high affinity for water was shown to dramatically enhance the tolerance to sulfur poisoning [5]. When used in combination with Ni as a composite anode, it is the only known SOFC anode that shows no sharp initial degradation upon exposure to the H2S (Fig. 1 B-D) [6].

Figure 1 (A) Ionic conductivities of BZCYYb, BZCY, GDC, and YSZ as measured at 400° to 750°C in wet oxygen (with ~3 vol%H2O) (YSZ and GDC are conventional electrolytes, denoting yttria stabilized zirconia and gadolinium doped ceria, respectively) (B) Schematic showing the two anodic reaction pathways for the Ni-BZCYYb/BZCYYb anode structure under fuel cell operating conditions (C) In-situ Raman spectra collected from BZCYYb samples under humidifed gas at various exposure times after a drying treatment at 400°C under evacuation for 10 hours (D) Impedance spectra measured under OCV conditions at 750°C for a cell with Ni-BZCYYb anode in clean H2 and in H2 contaminated with 20 ppm H2S

2. Designed a new anode nano-architecture and understood electrocatalytic reactions at the nanoscale

A new anode nano-architecture was designed and fabricated by a vapor deposition-in situ reduction technique [7-8]. Synchrotron-based grazing incidence angle X-ray diffraction and Ba LIII-edge X-ray absorption near-edge structure analysis showed that barium was present on the nickel surface in compound form, not as barium metal, and the barium compound was lacking long-range order. The advanced electron microscopy and spectroscopy further confirmed the nanoscale nature of barium oxide islands, creating numerous nanostructured barium oxide/nickel interfaces (Fig. 2 A-C). The anode with this unique architecture was shown to deliver the highest power density and stability in C3H8, CO and gasified carbon fuels. The electrocatalytic reactions on the surface of the nanostructured anode have been investigated by thermogravimetric analysis, Raman spectroscopy, mass spectroscopy and density functional theory calculations (Fig. 2 D-F). It was found that upon exposure in the humidified fuel, the anode exhibited a broad Raman mode between 3450 and 3700 cm-1, indicating the presence of water with weak hydrogen bonds. Further, H2O dissociation is more favorable near the oxide-metal interface region than on the oxide and metal surfaces. After adsorption on interfaces, H2O leads to a barrierless O–H bond cleavage and hydroxylated BaO. The dissociated OH then reacts with an adsorbed C on the Ni surface to form an intermediate COH, which is subsequently dissociated to CO and H. Finally, CO and H diffuse to a triple-phase boundary, where they are electrochemically oxidized to CO2 and H2O, respectively. These nanostructured interfaces promoted the water-mediated carbon removal reactions (a chemical process) on the exposed Ni surface but will not impede the charge transfer processes across the interfaces and along the surfaces (electrochemical processes) of the anode under fuel cell operating conditions.

Figure 2 (A-D) HRTEM, synchrotron based XANES, GISAXS, and in-situ Raman spectroscopy analysis of BaO/Ni-BZY/YSZ anode with amorphous BaO nanoislands and BZY thin films; (E-F) DFT prediction of water-mediated carbon removal on the anode with nanostructured interfaces

3. Determined intrinsic surface oxygen reduction reaction activity and developed a high-performance composite cathode

It is well established that intrinsic surface catalytic properties (ORR activity) of a cathode are difficult to investigate [9]. In this project, a new test cell platform was designed, as shown in Fig. 3 A [10]. With this design, the surface of working electrode can be readily studied under equilibrium and non-equilibrium conditions with fewer uncertainties stemming from the sheet resistance, current collection, and bulk ionic transport. A La0.6Sr0.4Co0.2Fe0.8O3-δ buried layer and a La0.85Sr0.15Mn0.8O3-δ thin-film working electrode demonstrated increased surface electrocatalytic activity upon polarization, resulting in faster surface exchange kinetics relative to uncoated La0.6Sr0.4Co0.2Fe0.8O3-δ (Fig. 3 B-C). This phenomenon is very different from the long-standing concept that La0.6Sr0.4Co0.2Fe0.8O3-δ possesses better surface catalytic activity than La0.85Sr0.15Mn0.8O3-δ which has been normally demonstrated under equilibrium conditions. A theoretical analysis of surface kinetics was used to understand the cathodic activation phenomenon. The electrochemical behavior simulated by the present model is qualitatively similar to that observed experimentally (Fig. 3 D). Based on the in-depth knowledge of cathodic reactions, a new composite cathode was developed for proton-conducting fuel cells [11-12]. Compared to the conventional oxygen ion-electron conducting cathode, this cathode is very active for oxygen reduction because it allows simultaneous transport of protons, oxygen vacancies, and electronic defects, extending the active sites for oxygen reduction to a large extent and significantly reducing the polarization resistance [13]. This cathode concept has been independently identified as a guideline for rationally designing high-performance cathodes [14-15].

Figure 3 (A) Schematic diagram of the new test cell configuration (B) HRTEM image at the interface between the two layers, showing epitaxy between the underlying LSCF and deposited LSM (c) Effect of cathodic overpotential on the interfacial resistances of blank LSCF and LSM-coated LSCF model electrodes (D) Simulated normalized interfacial resistance versus effective cathodic overpotential for blank LSCF and LSCF with modified surface properties, Ri is normalized to the value of the blank LSCF at OCV

SUMMARY

The discovery of the electrochemically active and stable electrolytes and electrodes has great potential to dramatically improve the economical competitiveness and commercial viability of low-temperature SOFCs that are driven by cost-effective and renewable fuels. Fundamental investigations of lattice dynamics, atomic environment together with anodic and cathodic reactions at surface and interface unravel the mechanisms responsible for improved electrical conductivity, enhanced sulfur and coking tolerance and accelerated oxygen reduction reactions. In conclusion, this report represents a critical step toward an economically feasible fuel cell for utilization of readily available fuels as well as demonstrates the significance of mechanistic study of structure-property relationship and surface- and interfaces-involved chemical and electrochemical reactions [16].

Reference

Wachsman E. D., Lee K. T. Science, 2011, 334: 935

Atkinson, A. et al. Nature Materials, 2004, 3, 17

Hibino, T. et al. Science 2000, 288, 2031

Yang, L., Wang, S., Blinn, K., et al. Science, 2009, 326: 126

Yang, L., Cheng, Z., Wilson, L., et al. Energy & Environmental Science, 2010, 3: 1804

Selman, J. R. Science, 2009, 326: 52

Yang, L., Choi, Y., Qin, W., et al. Nature Communications, 2011, 2: 357

Yang, L., Zuo, C., Liu, M.L. Journal of Power Sources, 2010, 195: 1845

Adler, S. B. Chemical Reviews, 2004, 104: 4791

Lynch, M., Yang, L. (equal authorship), et al. Energy & Environmental Science, 2011, 4: 2249

Yang, L., Zuo, C., Wang, S., et al. Advanced Materials, 2008, 20: 3280

Yang L., Liu Z., Wang S., et al. Journal of Power Sources, 2010, 195: 471

Yang L., Wang S., Lou, X., et al. International Journal of Hydrogen Energy, 2011, 36: 2266

Fabbri, E., Pergolesi, D., Traversa, E. Chemical Society Reviews, 2010, 39, 4355

Peng, R., Wu, T., Liu, W., et al. Journal of Materials Chemistry, 2010, 20, 6218

Yang, L.*, Cheng, S.*, Ding, Y., et al. Nano Letters, 2012, In press DOI: 10.1021/nl203600x

公安机关备案号:44040302000222

公安机关备案号:44040302000222